Attachment only, requires the now discontinued WSKTS-KO Sharpener for use. Does not fit fit the current Work Sharp Ken Onion Mk. 2 Sharpener.

The new Work Sharp Blade Grinding Attachment is available.

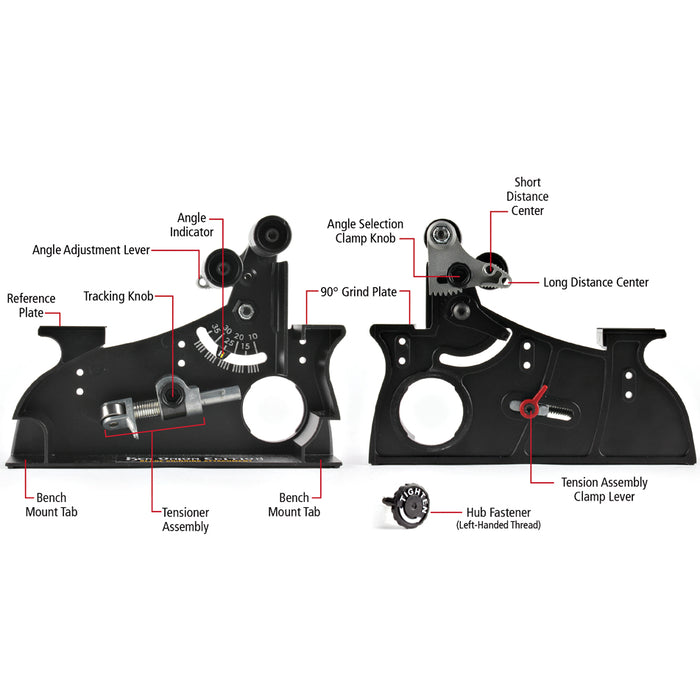

The WSKTS-KO Blade Grinding Attachment is a horizontal belt attachment designed for knife shaping, sharpening and honing tasks. The 4 pulley attachment is fully adjustable from 10° to 35° (in 1° increments) and includes 1” x 18” engineered abrasive belts in a wide range of grits.

Adjustable Profile

The top pulleys have two center distance positions so you can choose your preferred belt deflection to create the edge profile you want – a full convex or a flat convex. This allows you to customize your blade edge to best meet your needs or preference. This attachment is similar in design to what blade makers use and provides a wide range of adjustability so you can custom shape, sharpen and hone your blades at home without the cost or size of full scale blade maker’s equipment.

Durable Construction and Innovative Features

It is designed with cast metal components and engineered polymers to hold up to the rigors of heavy sharpening tasks. This attachment is quickly installed thanks to the tool-less design so changing belts and attachments is quick and easy. The belt speed is adjustable from 1200 SFM to 2800 SFM to accommodate a wide range of sharpening and honing tasks. A flat reference plate is provided so you can level your blade before you approach the belt (which determines your grind angle) and create a very consistent edge angle on your blade.

Adjustable Angles and Easy Use

Since the angle adjustment is done in the belt, the sharpening method is always the same – simply hold the blade horizontal and sharpen the length of the blade across the belt. Attachment also includes a flat work space that provides 90° angle access to the abrasive belt for various grinding tasks. The micro-adjust belt tracking knob ensures you keep your belt centered while working, without using tools or losing momentum. The spring tensioner with a sealed bearing has a lock out feature that makes belt changes fast and easy without the need for tools – simply push and turn the tensioner to install a belt in seconds. Whit it isn't intended for grinding or creating primary bevels into steel blade blanks, it is capable of shaping, profiling, sharpening, honing and stropping tasks on existing blades.

Work Sharp Engineered, Ken Onion Designed. Assembled in the USA.

Abrasive Belts

The Blade Grinder attachment provides a full selection of 1” x 18” abrasive grit belts. Premium 5-pc. belt selection provided: Norton ceramic P120, Norax X65 (P220), X22 (P1000), X4 (P1000) and Micro-Mesh 12000 so you can shape, sharpen, hone and strop all of your blades.

P120 Grit Belt - The P120 is a coarse belt that can be used for grinding or for fast stock removal from knives. This is a quality coated 1" fabric belt.

Norton Norax Belts

There are three 3/4" wide Norton Norax Belts included in the kit. The Norton Norax Belts utilize very consistent aluminum oxide abrasives. The belts have a depth to the abrasive surface unlike any other belts we carry. The depth to the abrasives allows the abrasives to break away and expose fresh abrasives below. This abrasive configuration allows it to run cooler, last 2 to 5 times longer, leave a very consistent finish and even cut faster. They are just great belts.

X65 Norax Belt - This belt features 65 micron aluminum oxide abrasive particles. This translates to roughly a P220 grit. This is a coarse belt that can be used for most coarse sharpening needs.

X22 Norax Belt - This belt features 22 micron aluminum oxide abrasive particles. This translates to roughly a P800 grit. This is a fine to medium belt that can be used to refine a coarsely sharpened edge or refine an edge that is starting to dull.

X4 Norax Belt - This belt features 4 micron aluminum oxide abrasive particles. This translates to roughly a P3000 grit. This is a very fine belt that can be used to put a very fine edge that is almost mirror polished.

12000 Grit Belt - The 12,000 grit belt is the finest belt. It is used for polishing or stropping. The belt itself feels very smooth to the touch.

Attachment Kit Includes:

- Cast Aluminum Grinder Chassis

- (1) P120 Extra Coarse

- (1) X65 Coarse

- (1) X22 Medium

- (1) X4 Fine

- (1) 12,000 Extra Fine

- Hub Flange Knob

- User's Guide

Sharpening Supplies Tests the Blade Grinding Attachment

We had fun testing the Work Sharp Blade Grinding Attachment. It feels like a smaller version of the industrial belt grinders favored by blade makers. While this won't take the place of industrial belt grinders, it offers many of the features at a smaller scale (and a smaller price as industrial belt grinders used by knife makers can easily cost thousands).

We first tested it on a large knife. This is where this unit really shines. On larger knives, the larger belts and stable base makes larger knives easy to handle.

WSKTS-KO Blade Grinding Attachment

- Attachment Only

- Works with the discontinued original Work Sharp Ken Onion Edition Sharpener.

- Tool-less Design Makes Changing Belts Easy

- Adjustable 10° to 35° (in 1° increments)