Tormek Tip - Turning Tool Setter

Mark the Turning Tool Setter for Accurate Set Up

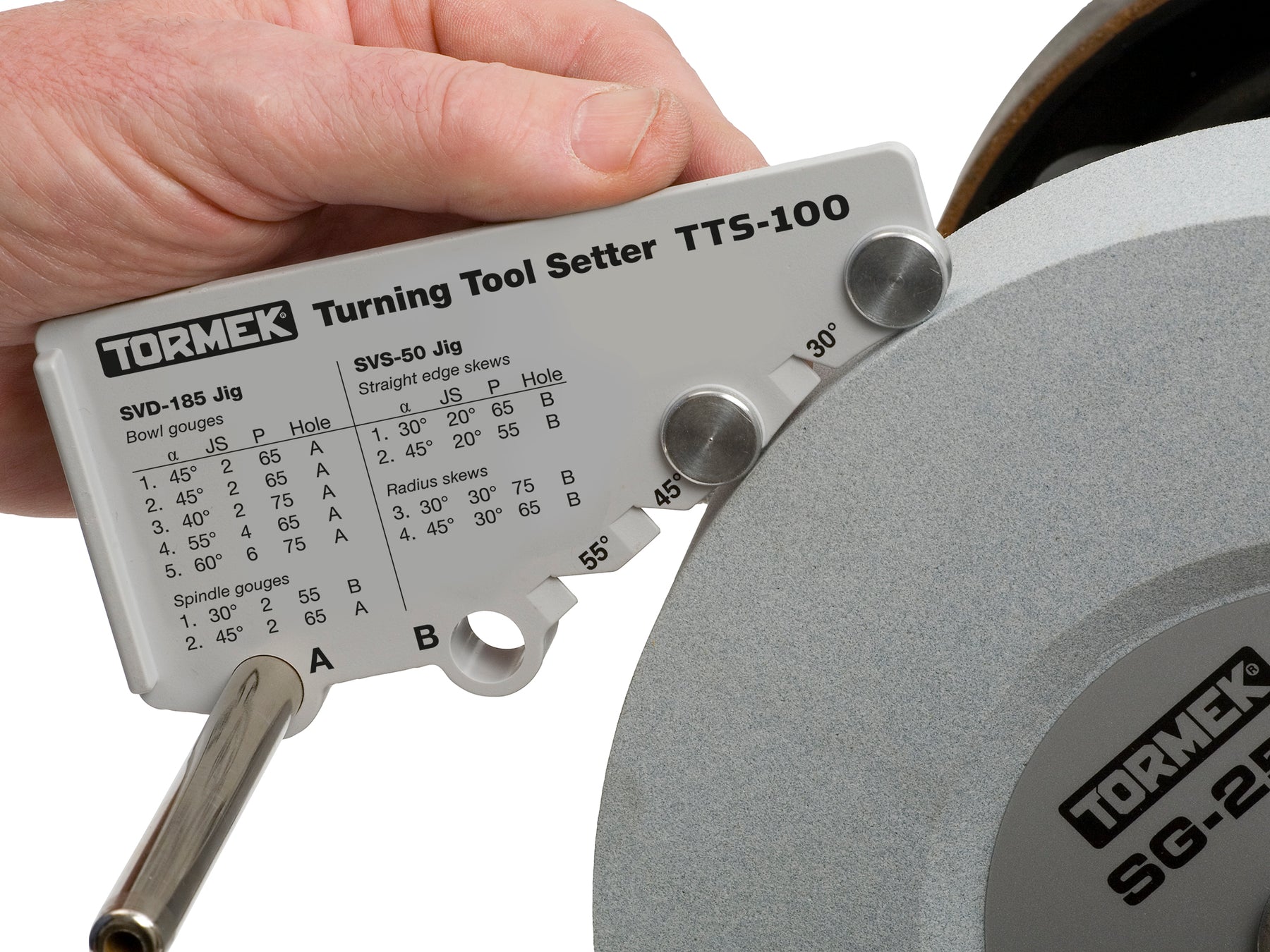

Tormek's TTS-100 Turning Tool Setter is an invaluable aid when sharpening turning tools with the SVD-186 Gouge Jig or the SVS-50 Multi Jig. Here's a tip to ensure the most consistent results when using the Turning Tool Setter.

The Turning Tool Setter

One of the functions of the Turning Tool Setter is to ensure the proper spacing of the Universal Support bar from the grinding wheel. This is done by sliding the Turning Tool Setter onto the Universal Support, using either Hole A or B as appropriate for the edge geometry you desire, then adjusting the support until both of the metal rollers are contacting the grinding wheel's surface.

Rotate the Grinding Wheel

Both metal rollers must be in contact with the grinding wheel to guarantee the proper positioning of the bar. If one of the rollers is not making contact with the wheel, then the spacing of the bar will not be correct.

To make certain that both rollers are in contact with the wheel, the easiest thing to do is to turn the grinding wheel by hand and watch to see that the rollers on the Turning Tool Setter are rotating.

Tip - Mark the Rollers

We recommend using a permanent marker to put a mark on each of the two rollers found on the Turning Tool Setter.

Now You Can See The Rollers Turn

Placing marks on the rollers makes it easy to tell if they are rotating as you hand turn the grinding wheel. When both rollers are turning, your Universal Support bar spacing is correct.

The Tormek Sharpening System is extremely versatile and useful, capable of reproducing complex grinds with extreme precision and consistency. I hope you enjoyed this Turner Tool Setter tip.

We stock a complete selection of Tormek machines and accessories. We also have trained staff that can assist you with your Tormek purchase, before and after the sale.