How Often Should I Flatten My Water Stones?

Water stones are a fantastic option for achieving a razor-sharp edge on your knives and tools. However, to keep them performing at their best, it’s crucial to maintain them properly. One of the most important aspects of water stone maintenance is flattening. In this article, we’ll answer the common question, “How often should I flatten my water stones?” and explain why flattening is necessary and important.

Why Flattening Water Stones is Important

Water stones wear down unevenly over time, resulting in a concave shape known as dishing. This dishing can severely impact the effectiveness of your sharpening efforts. Here’s why flattening your water stones is so important:

Consistent Sharpening Angle

A flat stone ensures that you maintain a consistent sharpening angle, which is crucial for achieving a sharp edge.

Effective Sharpening

Flat stones provide even contact with the blade, leading to more efficient and faster sharpening.

Longevity of the Stone

Regular flattening extends the life of your water stones by preventing severe dishing and the need to remove more material during maintenance.

Better Results

Ultimately, flat stones produce better sharpening results, giving you a sharper, more durable edge.

How Often Should You Flatten Your Water Stones?

The frequency of flattening your water stones depends on several factors, including the grit of the stone, the type of stone, and how often you use it. Here are some general guidelines:

Water Stone Grit

Shapton GlassStone water stones.

Within any line of water stones, the lower grits are going to wear faster. They’re composed of larger abrasive particles and they often get put to use to remove the most amount of steel from a tool. If you’re sharpening a very blunt or damaged edge, you need your low grit stones for their ability to remove metal fast. During this stage you will likely also be creating a new bevel on the tool. Having a flat sharpening stone to create a flat bevel on your tool is essential.

As you work your way into finer grits, these stones tend to be harder and wear slower. You should also be using less pressure since you no longer need to remove a lot of material. So finer grit stones will likely require less frequent flattening.

Stone Composition

Synthetic sharpening stones are made of an abrasive held together in a binder. The type of abrasive and the composition of the binder will impact how quick they wear. Some stones are formulated to be hard wearing, so they will require less frequent flattening. Other stones will wear quickly but are often faster cutting.

Naniwa Standard Traditional 220 grit green carbide and pink alumina water stones.

A good example of this would be the two 220 grit Naniwa Standard Traditional Stones. The T-102 uses green carbide which cuts faster, while the T-901 uses pink alumina, which wears slower. These stones are the same grit, in the same Standard Traditional line of stones, but their composition means that you would have to flatten the T-102 sooner than the T-901.

Premium water stones will have a good balance of slow wear and fast cutting. For example, Shapton’s GlassStones are slow wearing and would typically require flattening less often than their Kuromaku stones.

Natural stones tend to be a little harder and less prone to dishing than synthetic stones, partly due to them generally being fine grit stones. If you primarily use natural stones, you may not need to flatten them as frequently.

Sharpening Frequency

It should be obvious that the more frequently you use your water stones, the sooner you’ll need to flatten them. If you use your stones infrequently, a good practice is to give them a quick lapping after every sharpening session. Staying on top of your maintenance could mean spending less than a minute on a flattening plate.

If you’re using your stones more intensely, such as repairing a very dull or damaged edge, you might need to pause sharpening in order to do some flattening. In addition to keeping the sharpening surface flat, you’ll also be clearing away swarf (metal particles) and exposing a fresh layer of abrasives, which can help keep your water stones cutting quickly.

Tool Type

Certain tools, like chisels, plane blades, and straight razors, benefit from being sharpened on a very flat stone. If you’re about to sharpen such a tool, it’s good practice to make sure your stones are flat before you begin.

Other tools, like kitchen knives, can still be sharpened effectively on a stone that isn’t perfectly flat. You’ll get better results on a flat stone, but you can still improve your edge if the stone is slightly dished.

That said, frequent flattening is also beneficial to maximizing the lifespan of your stones. So if you notice that your stone is not longer flat, take it to your lapping plate or flattening stone.

For information on flattening techniques, read our article How To Flatten a Water Stone.

How to Check Water Stone Flatness

To check if your water stones are flat, use a straight edge or a tool you know to be perfectly flat. Place it across the stone and hold it up to a light source. If you see light between the stone and the straight edge, it’s time to flatten your stone.

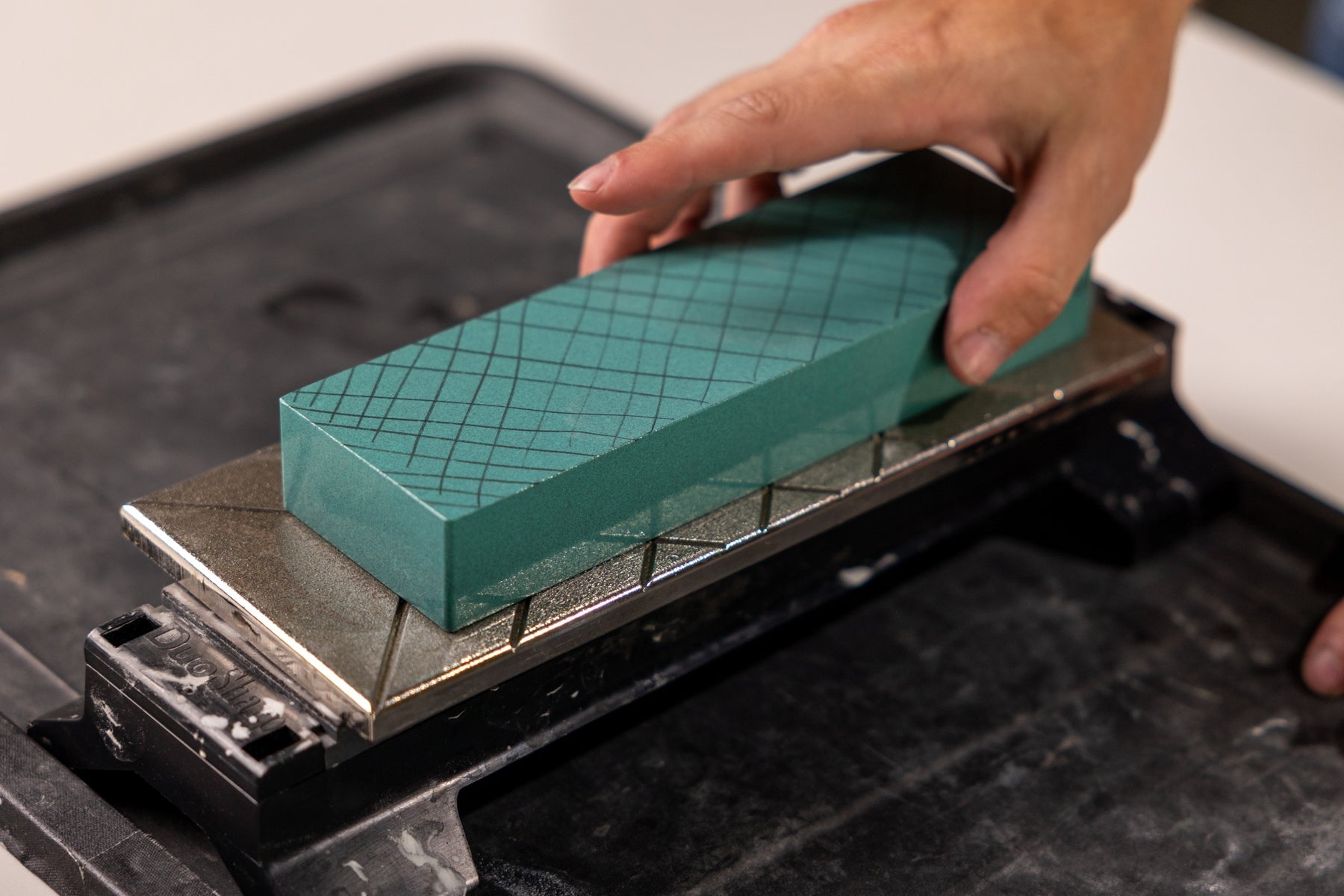

Alternatively, use a pencil to draw a grid pattern on the surface of your stone and start flattening. If the grid pattern is not removed evenly, the areas where it does get removed indicates there are high spots that need to be flattened.

Water Stone Flattening Options

Flattening Stones

Norton, Sharpening Supplies and Naniwa flattening stones.

This option shares many of the characteristics of water stones. They usually use silicon carbide abrasives and typically have deep grooves in their surface to help clear slurry from the cutting surface. These are often the most cost-effective option.

Diamond Lapping Plates

Nano-Hone, DMT, and Shapton diamond lapping plates.

Diamond plates, such as the DMT Dia-Flat Lapping plates, are excellent for flattening water stones. They will remain perfectly flat throughout their lifespan and provide a quick and effective way to flatten your stones.

Loose abrasive

Edge Pro Stone Leveling Kit.

Some lapping system use loose abrasive applied to a flat surface, typically either metal or glass. These systems allow you to use different grits depending the stones you’re trying to flatten.

For a more detailed look at the different flattening options available you can read our article Selecting a Lapping Plate for Water Stones, or browse all our available Lapping Plates & Flattening Stones.

Tips for Maintaining Flat Water Stones

Little and Often

Adopt the mantra “little and often.” Spending a minute flattening your stone after each session is much easier than dealing with a severely dished stone later.

Regular Checks

Make it a habit to check your stones regularly with a straight edge. This simple step can save you a lot of time and effort.

Consistent Maintenance

Regular maintenance ensures that your water stones stay in top condition, providing better sharpening results and extending the life of the stones. For more tips on looking after your water stones, read our article 5 Essential Care Tips For Your Water Stones.

When you purchase a water stone you are getting something that will last you many years. Flattening often means you only have to remove the bare minimum material. Over time, this approach will give you the best sharpening results and extend the life of the stone

By following these guidelines, you can keep your water stones in excellent condition and achieve the sharpest edges possible. Shop our selection of flattening tools and water stones to keep your sharpening setup in top shape.