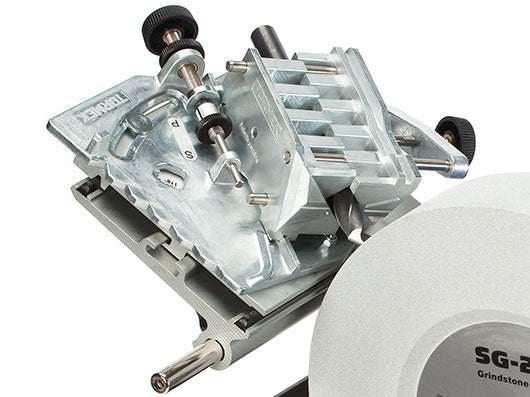

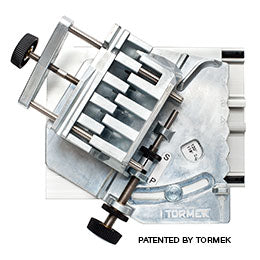

With the Tormek patented attachment for drill bits DBS-22 you can now sharpen your drill bits with the highest precision. The optimal point and clearance angles can be set according to each drilling requirement, which depends upon the drill bit size and material. You can completely restore worn or broken drill bits to a perfect shape.

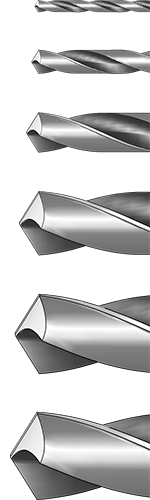

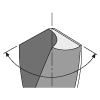

You create a 4-facet point which gives the ideal cutting performance since the chisel edge gets a point instead of being almost flat as on many drill bits. A 4-facet point will not walk and the thrust force required is considerably reduced compared to a conventional cone point drill bit.

A precision sharpened 4-facet point generates less heat and the life of the drill bit is therefore also prolonged. Independent tests show that a Tormek sharpened drill lasts up to 4 times longer than a brand new conventional drill bit¹.

By working with the laws of physics and cooling the edge continuously, the risk that the steel becomes overheated and loses its hardness or gets micro cracks is eliminated. You have full control all the time and can see how the sharpening proceeds. Will work on all Tormek models.

Flexibility and Precision

|

4-Facet point |

|

|

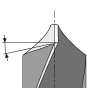

Always equal cutting edges |

|

|

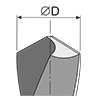

Sharpens all point angles |

|

|

Always the right clearance angle |

|

|

Sharpens a wide range of drill sizes |

Parts

Base Plate |

Guide |

Setting Template |

Drill Holder |

|

Instruction |

Magnifier |

Questions & Answers

Why is the 4-facet point so beneficial compared to a conventional point?

It considerably decreases the force required on the core of the drill, i.e the chisel edge, which reduces the heat development and permits an increased force to the cutting edges. It gives the drill a dramatic improvement in cutting performance.

Why does a Tormek sharpened drill last longer?

The beneficial 4-facet point and the high precision sharpening - both cutting edges are sharpened to an exact equal length and symmetrically - make the drill work efficiently and the life of the drill bit is considerably prolonged.

What determines an exact and straight hole?

The 4-facet geometry causes the drill to bore a straight and round hole with very close tolerances. It is crucial that both cutting edges are equal and sharpened to the same angle. This is an essential requirement so that the two edges will work in the same way and ensures that the drill will bore a straight hole, which is not larger than the drill diameter. Otherwise, the longer edge will take most of the cutting force, get overheated and more heavily worn. The result is a drill that will dull rapidly and stop working properly.

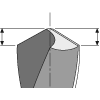

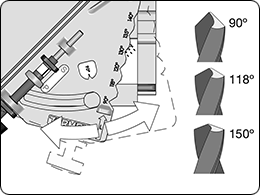

What point angle should I have?

Drill bits usually have a point angle of 118° or 130°. Hardened steel and stainless steel require larger point angles. Also aluminium is best drilled with a larger point angle. When drilling plexiglass, the risk of cracks when the drill goes through the material is reduced with a larger point angle. Centering drills usually have a 90° point angle.

Is the clearance angle important?

The choice of clearance angle is crucial to the cutting performance and duration of the drill. The optimal clearance angle depends both on the drill diameter and the material to be drilled. A harder material requires a drill with a smaller clearance angle while a softer material can have a larger angle. Standard drills have a clearance angle of 11° and a 118° point angle which work well for most drilling work.

How do you know if the steel has become overheated when using a dry grinder?

Overheating of the steel is often not noticeable, but the consequences are that the drill will dull rapidly and may even break. Unlike conventional drill bit sharpeners, Tormek sharpens with water cooling which is gentle on the steel.

This is How The Attachment Works

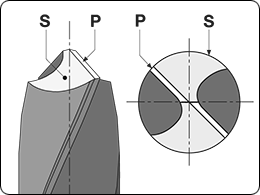

The Primary facets, P and the Secondary facets, S meet in the centre and form a point. |

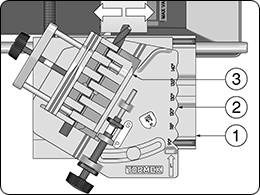

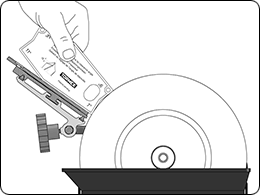

The drill is mounted in a Drill Holder (3) on a Guide (2), which in turn runs on a Base (1). |

|

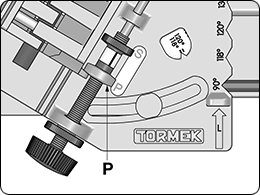

You start by sharpening the Primary facets. The grinding depth is determined by a setting screw, P. |

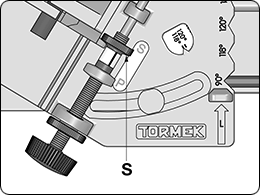

The drill holder is moved forward to a second stop S for grinding the Secondary facets. |

|

The Point angle can be set at any angle by turning the guide. Select the angle which is most suitable for the job… |

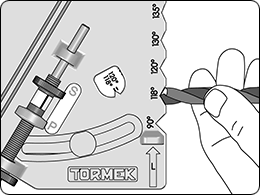

...or first measure the existing point angle in the grooves on the Guide. |

|

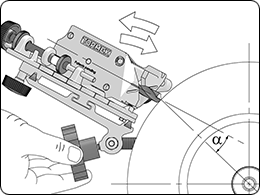

The Clearance angle is set by tilting the base… |

...it can easily be set with the Setting Template. |