Diamond Abrasive with Water Stone Style

You may know Naniwa for their high quality water stones, however you may not know they also make an impressive line of diamond abrasive stones. But the Naniwa Diamond Pro Stones are a different approach to diamond abrasive stones than what you may be familiar with.

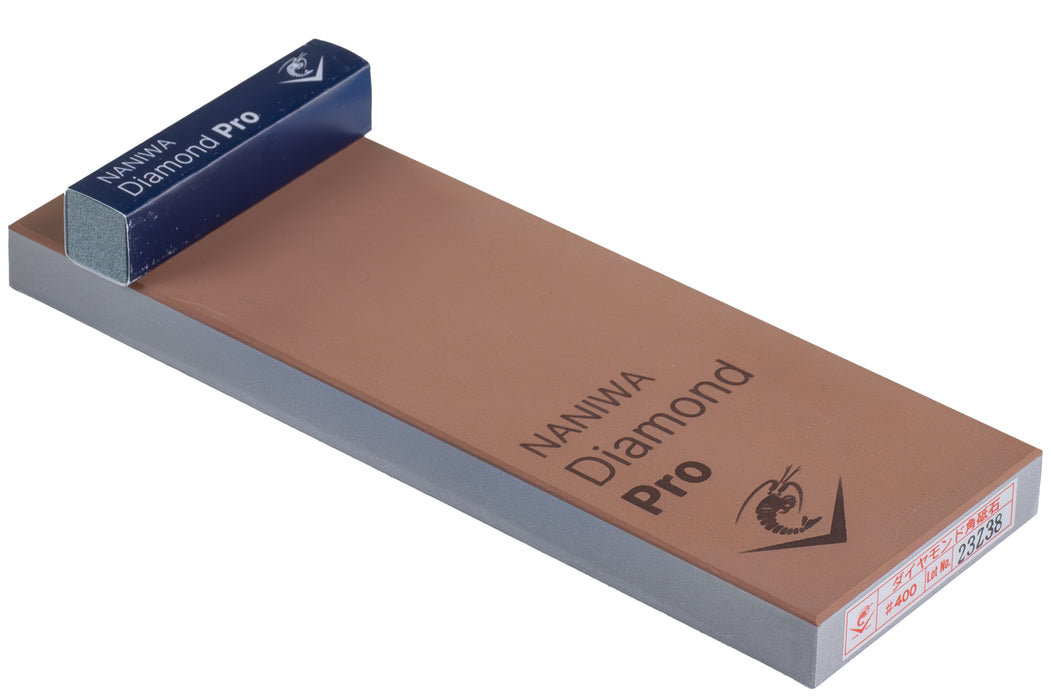

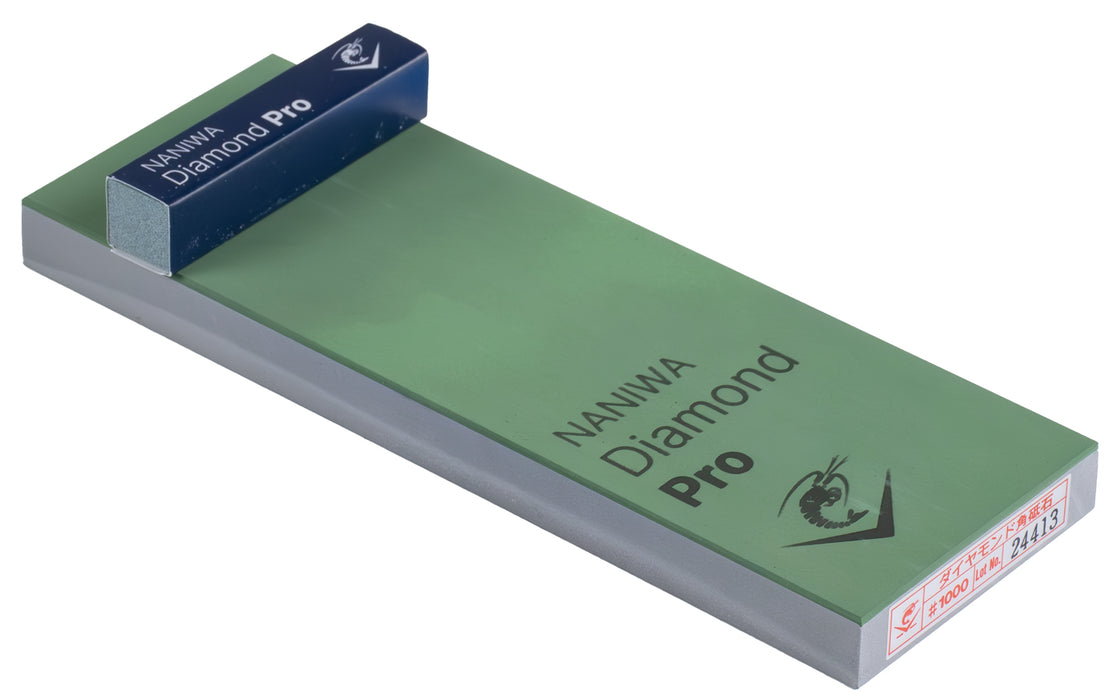

These stones employ diamond abrasive bound in layer of resin mounted to a sturdy metal base. Rather than the single layer of diamonds found on many other diamond abrasive plates, the diamond abrasive layer on these stones is 1mm thick. This layer of diamond impregnated resin allows the stone to shed worn or loaded layers to expose a fresh cutting surface. This slow shedding of worn surface makes for a water stone sharpening experience with diamond abrasives that can handle the hardest sharpening situations.

Splash and Go

A light spray of water and Naniwa Diamond Pro Stones are set to sharpen. Their feel when sharpening is similar to that of the hardest wearing water stones, neither unduly rough nor mushy or clay-like. As with all water stones, keep Naniwa Diamond Pro Stones wet when sharpening and allow them to air dry in between uses.

Naniwa Diamond Pro Stones are 210mm (8-1/4") x 75mm (2-7/8") x 16mm (5/8") making them suitable for a wide range of knives and tools.

For Very Hard Steels and Ceramics

Naniwa Diamond Pro Stones are particularly useful when you want a water stone style sharpener, but are working with extremely hard exotic steel or ceramic. Other stones may be very slow or even ineffective for ceramic or the hardest steel knives, chisels and plane blades, but because they are diamonds, if the abrasive in these stones won't sharpen the edge, nothing will.

Stones that Stay Flat Longer

The Naniwa Diamond Pro Stones do not wear as quickly as other water stones. The resin binder that holds the abrasive material is very hard, making them slow to dish or cup, and long lasting. These stones are handy when performing tasks where flatness is of primary importance, as when flattening chisel backs or working the ride line on hair cutting shears.

Dressing Stone Included

Each Naniwa Diamond Pro Stone comes with a smaller dressing stone. The dressing stone is used to keep the Diamond Stone clean and cutting optimally. When the Diamond Stone begins to darken with the waste metal from sharpening, rub its surface with the dressing stone. Using the dressing stone will expose a fresh, clean surface on the Diamond Stone allowing it to sharpen with maximum efficiency. For best results, the surface of the diamond stone should be wet and the dressing stone should be soaked until saturated before use.

Naniwa Diamond Pro Stone

- Diamond Abrasive

- Hard Wearing - Stays Flat Longer

- For Very Hard Steels

- For Ceramics

- Includes Dressing Stone

- New Packaging