For Kitchen or Shop

Nano-Hone Diamond Resin Plates provide high tech sharpening. Use them in your shop or bring them into the kitchen. Whether you are sharpening tools or honing fine culinary knives, the comprehensive Nano-Hone system of stones, holders, ponds and strops is equally easy to use on a work bench or over a kitchen sink. Nano-Hone stones are perfect for the craftsman or chef who is particular about their edges.

A Different Kind of Diamond Stone

These stones made of diamonds held in a 1.2mm thick layer of resin binder. Unlike most other diamond stones which are a single coating of diamonds plated onto a base, the Nano-Hone Diamond Resin Plates provide a feel more like a water stone. As the resin slowly wears, fresh diamonds are exposed making for a fast cutting, long lasting stone. Cut very hard blades like powdered steels with ease. These plates can be used dry or with water

The resin the diamonds are bound in is specifically designed to be hard enough for the plate to be slow wearing, but unlike many other diamond in resin stones, it is soft enough to be efficiently flattened. The Nano-Hone NL-4 Diamond Flattening Plate is the recommended lapping surface for the Diamond Resin Plates.

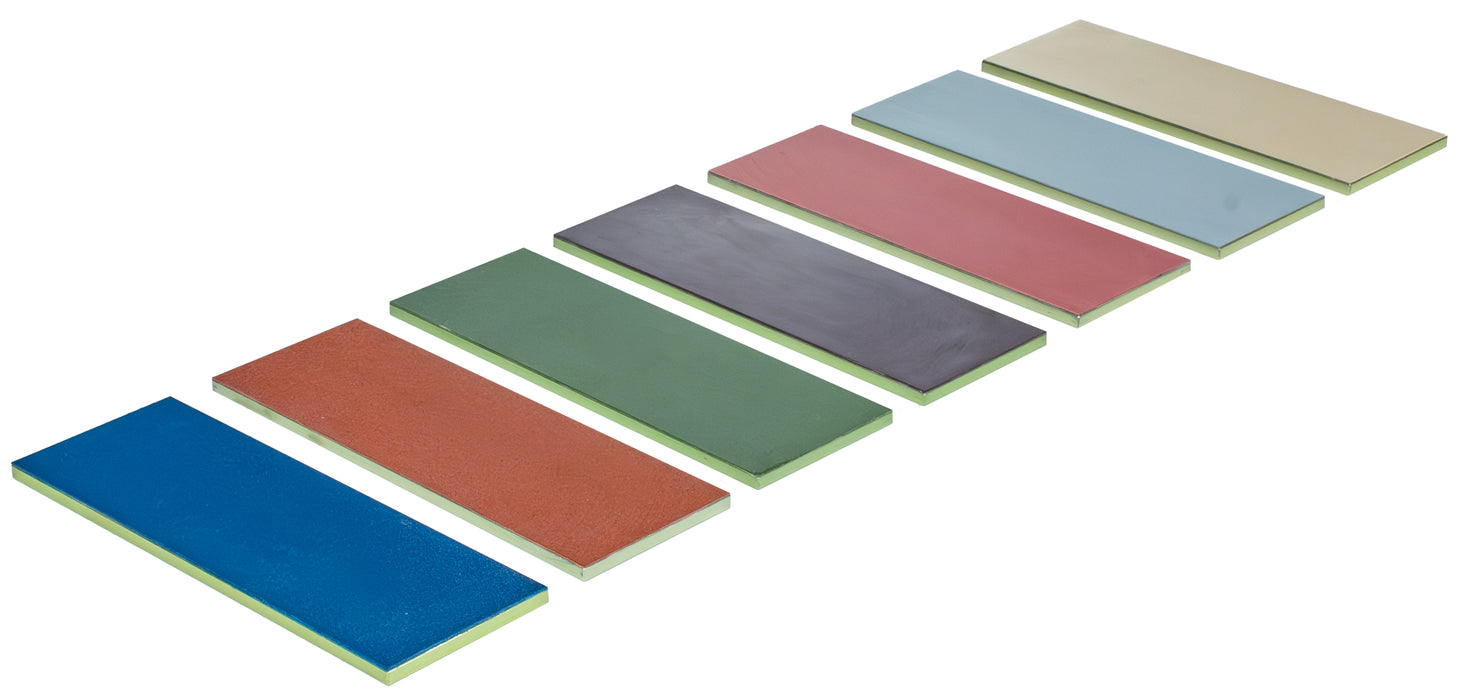

Choose From Three Grits

The Nano-Hone Diamond Resin Stones are available in three grits:

- DR-200, 200 Micron / ~80 Grit

- DR-100, 100 Micron / ~160 Grit

- DR-50, 50 Micron / ~360 Grit

- DR-25, 25 Micron / ~600Grit

- DR-10, 10 Micron / ~1,500 Grit

- DR-3, 3 Micron / ~5,000 Grit

- DR-1, 1 Micron / ~10,000 Grit

Part of the Nano-Hone System

The Nano-Hone Diamond Resin Stones are designed to work with the Nano-Hone Stone Stage. Each stone's Aluminum Base Plate has two holes which fit on to pins on the massive Stone Stage stone holder for a stable sharpening experience.

To get even more from the Nano-Hone sharpening experience, put your Nano-Hone Stone Stage in the Nano-Hone Sharpening Pond to keep the water contained.

Generous Size

The Nano-Hone Water Stones measure 210 mm x 75 mm (8" x 2 7/8") providing ample room for sharpening. The abrasive layer is 1.5mm thick for a long service life. The Aluminum Base Plate is 6mm (1/4") thick making for a sturdy stone.

Q. Some of the stones list only a micron number, not a grit number. Why?

A. Nano Hone prefers to work by micron number and does not provide grit numbers for all their stones.

Q. What is the difference between micron and grit numbers?

A. Micron numbers are a precise measurement of the size of the abrasive particles in microns (1/1000th of a millimeter). The larger the micron number, the larger the size of the abrasive particles. Grit numbers are measurements of the filters used to sort abrasive particles. The larger the grit number, the smaller the abrasive particles.

Q. Why does Nano-Hone prefer micron numbers?

A. Because of the precision and consistency of micron numbers. While micron numbers are precise, grit numbers are not. Grit numbers also have the complication of the existence of several different scales used to determine them. These scales do not line up with one another, so a 1000 grit in one scale is not the same as a 1000 grit in another scale.

Nano-Hone Solid Surface Diamond Resin Plates

- For Kitchen or Shop

- Diamond Abrasive in Resin

- Hard Wearing but Flattenable

- Use Wet or Dry