Difference in Sharpening Stone Materials

Selecting A Sharpening Stone:

Understanding The Differences In Materials

The three most common types of sharpening stones are water stones, diamond stones, and oil stones. Each of these stones has its own advantages that can help users achieve their sharpening goals. Below we'll get into into the differences between each sharpening stone material.

Water Stones

Water stones have become very popular due to their many performance advantages. Water stones are available in both natural and synthetic materials. However, the vast majority of water stones are man-made so we'll discuss those specifically.

Water stones are often made of Aluminum Oxide abrasive material. This is the same abrasive material found in oil stones like the Norton India Stones. The difference between a water stone and an oil stone is the binder that holds the abrasives together. Water stones are softer than oil stones. This softer binder promotes faster cutting because the old abrasive material breaks away and is replaced with fresh sharp material.

Fast cutting is a clear an advantage of the water stone. It is also available in a much wider range of grits than most other stones. Water stones are available in grits as coarse as 120 grit and easily found in grits above 8000 (the finest being 30,0000).

The other obvious advantage is the use of water rather than oil to remove the swarf (metal particles created during sharpening) from the stone. Water not only cleans up easier, but it is something that is almost always readily available.

The softness of the water stone does have one downside. As the stone wears, it must be flattened periodically. For this reason, when owning a water stone, a Flattening Stone is highly recommended.

Our most popular lines of water stones are the Naniwa Advance Super Stones, Naniwa Chocera Pro Stones, Shapton Kuromaku, Shapton GlassStones, , and Sharpening Supplies Water Stones,.

Diamond Stones

DMT Duo-Sharp

Diamond stones contain diamonds bonded to a metal surface. These industrial diamonds are the hardest abrasive material designed for sharpening stones. These popular sharpening stones are available in a variety of sizes, shapes and grits.

There are two different types of diamond stone. Diamonds bonded to a metal surface and diamond resin stones. Diamonds bonded to a metal surface are much more common and are available in two varieties: interrupted or continuous surface. Interrupted diamond surface sharpening stones contain holes in the diamond surface to capture the swarf. These stones cut very fast and are often more economical. Examples of this style are the DMT Duo-Sharp line of diamond stones. The next type, a continuous diamond surface, includes the popular DMT Dia-Sharp line of diamond stones. The continuous diamond surface is preferred when you are sharpening tools with points that might get caught in the recesses of the interrupted diamond surface.

DMT Dia-Sharp

Diamond stones are available in mono-crystalline and poly-crystalline diamonds. The mono-crystalline diamonds are more desirable as they will last longer. The DMT stones we carry are all mono-crystalline diamonds.

Diamond stones have key advantages over other types of sharpening stones. Diamond stones are the fastest cutting sharpening stones. Speed is especially helpful when working with coarse grits where you may spend additional time on a dull edge. Diamond stones are extremely flat and stay flat over the lifetime of the stone. This is extremely helpful when sharpening tools that require an absolutely flat stone. Diamond stones are also the easiest to maintain, simply dry the stones after use.

Diamond stones are widely available in grits from 220 to 1200. The finest grit diamond stone that is widely available is 1200 grit. In recent years, DMT has made a 4000 and 8000 grit diamond stone available. For finer grits, it is a common practice to use water stones after diamond stones for the finest polishing grits.

The most popular lines of these diamond stones are the DMT Duo-Sharp and the DMT Dia-Sharp lines.

Diamond resin stones have a diamond abrasive bound in a layer of resin mounted to a sturdy metal base. Naniwa Diamond Pro Stones have a 1mm layer of diamond abrasive and are available in six grits, from a coarse 400 grit, to a very fine 6000 grit. The Nano-Hone Diamond Resin Plates have a 1.2mm thick abrasive layer and are available in seven grits from a very coarse 200 µm (approximately 80 grit), to an extremely fine 1 µm (10,000 grit).

Oil Stones

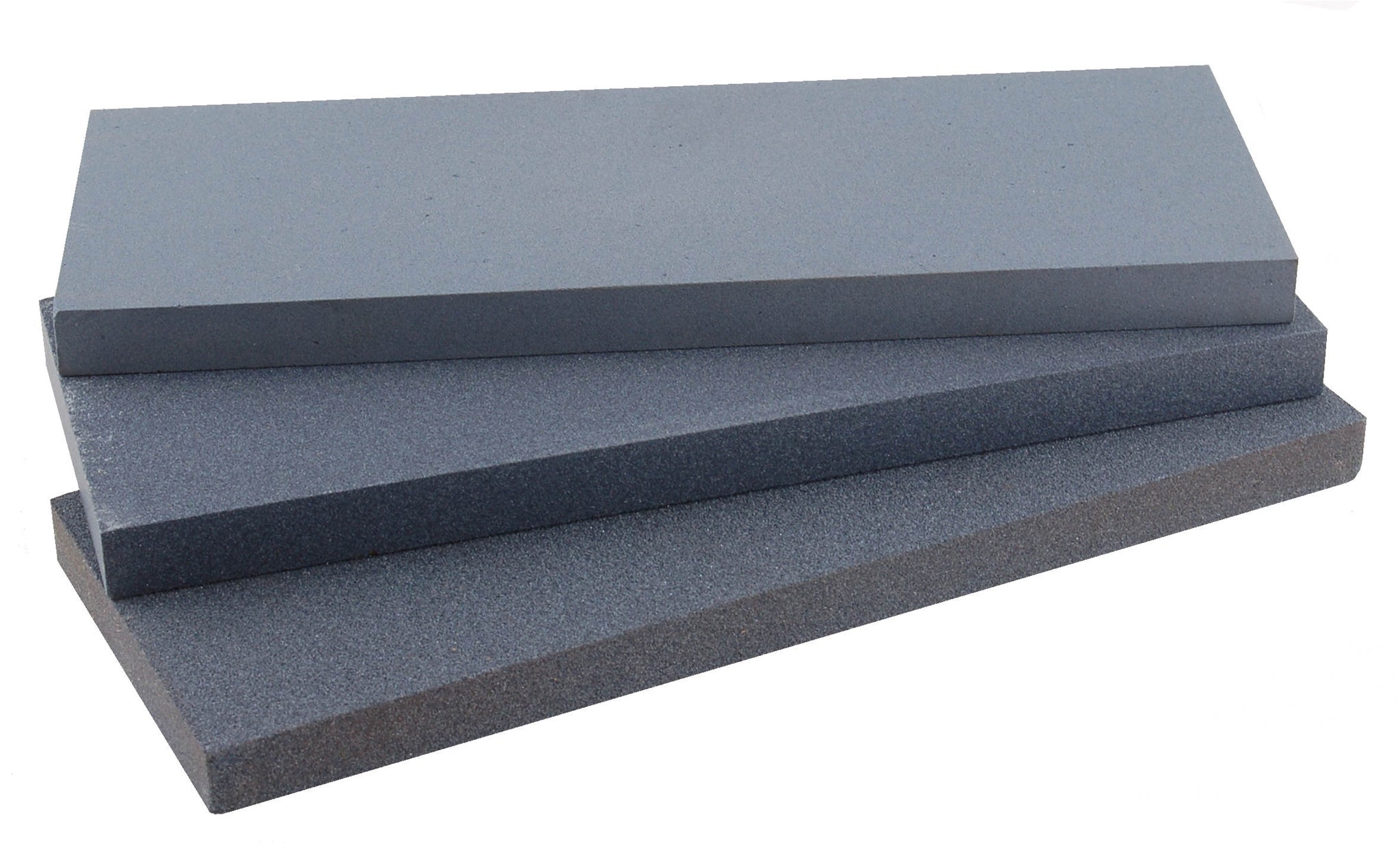

Oil stones are the traditional stones that many people grew up using. These have been commercially available in the USA for many decades. Compared with water stones, oil stones are harder stones. These stones are made from one of three materials (Novaculite, Aluminum Oxide, or Silicon Carbide) and use oil for swarf (metal filing) removal and to keep the stones from clogging.

The original traditional oil stones are natural stones made from Novaculite. These natural stones are quarried in Arkansas and processed to make what we call Arkansas Stones. These stones are separated into different grades related to the density and the finish a stone produces on a blade. The coarsest of them are called Washita. The Washita is not often used these days because it is very soft and the coarse job is easier handled by man-made oil stones. The finer grades are called Soft Arkansas, Hard Arkansas, Hard Black Arkansas and Hard Translucent Arkansas. These natural oil stones can produce a polished edge, but tend to cut more slowly than man-made stones. The Hard Black Arkansas and Hard Translucent are rarer and are therefore more expensive.

The Aluminum Oxide oil stones are a very popular man-made choice. The most popular are called the Norton India Stones. These stones can cut fast, and can also produce a fine edge on tools and knives. The grading system for these stones is generally labeled fine, medium, and coarse. These stones are often brown or orange in color. When compared with the Arkansas stones, Aluminum Oxide (India Stones) are more coarse. The India Stones are used in conjunction with Arkansas Stones to cover the grit range.

The fastest cutting oil stones are made of silicon carbide stones. The silicon carbide stones made by Norton are called Norton Crystolon Stones. These stones are also labeled fine, medium, and coarse. They are usually gray in color. While these stones will not produce an edge as fine as the India or Arkansas stones. The fast cutting property makes them ideal for initial coarse sharpening. Because they sharpen quickly, it is a common practice to use the Coarse Crystolon and then progress to an India Stone and then to finish up on an Arkansas Stone.

The good overall performance and the lower price are the oil stone’s greatest assets. A set of India or Crystolon stones are the least expensive stones to purchase. Natural Arkansas Stones vary in price from the very economical Soft Arkansas to the more expensive Hard Black and Translucent Arkansas Stones. All oil stones stones are relatively hard, so the stones rarely require flattening.

The main disadvantage of the oil stone is its slower cutting rate. Of the three main stone types, the oil stone is the slowest. The fact that oil is used to remove the swarf is also messier to clean up than water.

We stock a wide range of Norton India Stones, Norton Crystolon Stones and Arkansas Stones.